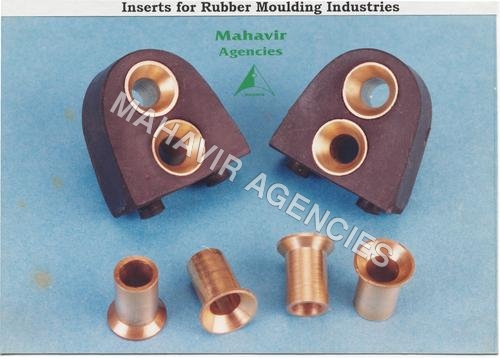

Rubber Moulding Brass Insert

Rubber Moulding Brass Insert Specification

- Torque

- Up to 2 Nm (varies by model)

- Thickness

- As per Custom Specification

- Drive Type

- Slotted, Allen

- Finish

- Bright Finish, Polished

- Corrosion Resistant

- Yes

- Grade

- CW614N, CW617N Brass

- Thread Type

- Metric, UNC, UNF, BSP

- Diameter

- 4 mm to 32 mm

- Load Capacity

- Up to 1200 N (varies by size)

- Standard

- DIN, IS, BS, ASTM

- Head Type

- Round, Knurled, Hex

- Capacity

- Custom as per requirement

- Fasteners Type

- Threaded Insert

- Material

- High Quality Brass

- Tolerance

- 0.05 mm

- Application

- Rubber Moulding, Plastic Moulding, Electrical & Automotive Fittings

Rubber Moulding Brass Insert Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200000 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Boxes

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Rubber Moulding Brass Insert

Rubber Moulding Brass Insert

We are manufacturer and exporter of Rubber Moulding Brass Insert. We have wide range available in brass inserts. We can provide in Round Inserts, Hex Inserts, Square Inserts, Knurling Inserts, Threaded Inserts and as per customer's requirement.

Material

Free Cutting Brass IS 319 Type (l)

Free Cutting Brass as per BS 249 Type(I)

Generally Free Machine Grade of CuZn37Pb3 equivalent to BS 2874 is used to manufacture various brass threaded inserts in form of round, Hexagon, Square etc

Other grades which are followed as per custom requirements are CZ 121, CZ 131, C3604, CDA 360, and DTD 627 etc

High Grade Free Cutting Brass.

Any Special Brass Material Composition as per customers requirement

Threads

ISO Metric (MM Threads)

BA Threads

BSW Threads (Inches)

UNC, UNF,UNEF and NPT Threads

BSP & BSPT (Parallel & Taper Threads)

Any threads as per specifications

Features

Thread as per international Go and Not Go Gauge Standard.

Deep Groove for maximum Pull out Resistance.

Inner Diameter (ID) after threading with very close tolerance to prevent unrequired flush to enter into brass inserts.

Application

Plastic Industry

Rubber Industry

Electronic Industry

Electrical Industry,etc...

Versatile Installation Methods

These brass inserts support press fit, ultrasonic, and heat fit installation techniques. Each method is suitable for various moulding processes, allowing easy adaptation to your manufacturing setup and ensuring stable, secure placement in your assemblies.

High Quality Brass and Precision Engineering

Crafted from CW614N and CW617N grades, our inserts are CNC turned to achieve a tight 0.05 mm tolerance. This results in consistent quality and optimal performance in demanding environments, from electrical fittings to automotive applications.

Customisation for Unique Requirements

We offer a broad range of diameters, threading types, head styles, and finishes. Custom options are available to meet specific dimensions or load requirements, helping you integrate these inserts seamlessly into new or existing products.

FAQs of Rubber Moulding Brass Insert:

Q: How are the Rubber Moulding Brass Inserts installed?

A: These inserts can be installed using press fit, ultrasonic, or heat fit methods. The chosen technique depends on the moulding process and material, ensuring secure placement and optimal performance.Q: What types of applications can use these brass inserts?

A: They are ideal for rubber and plastic moulding, as well as electrical and automotive fittings. Their corrosion resistance and robust threading support a wide range of fastening and assembly needs.Q: When should I choose a press fit vs. heat fit or ultrasonic installation?

A: Press fit is suitable for rigid substrates, while heat fit works well with thermoplastics. Ultrasonic installation is recommended where fast and secure integration is needed in softer plastics or rubber-based materials.Q: Where are these brass inserts commonly used?

A: Our inserts are widely implemented in manufacturing facilities for electrical components, automotive parts, and moulded plastic or rubber assemblies, both domestically and for export markets.Q: What is the manufacturing process for these inserts?

A: The inserts are CNC turned from high-quality CW614N or CW617N brass, meeting international standards such as DIN, IS, BS, and ASTM. Precision machining ensures consistent shape, threading, and structural integrity.Q: How does the customisation process work?

A: You can specify dimensions, thread and head types, finishes, and packaging. We accommodate varying load capacities and torque values tailored to your requirements, with a minimum order quantity of 1,000 pieces.Q: What are the benefits of using these brass inserts?

A: They offer excellent corrosion resistance, high mechanical strength, reliable long-term service over five years, and versatile installation compatible with diverse assembly processes. Their bright finish and precision build enhance product quality and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Moulding Inserts Category

Brass Hex Inserts

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 5000 Pieces

Material : Brass

Application : Plastic Moulding, Electronics, Automotive, Furniture

Surface Treatment : Other, Nickel Plated, Natural Brass, Gold Plated

Hardness : 65100 HV

Brass Square Nut Inserts

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 10000 Pieces

Material : Brass

Application : Plastic Moulding, Automotive, Electrical & Electronics, Furniture Fittings

Surface Treatment : Other, Nickel Plated, Natural Brass Finish, Chrome Plated, Tin Plated

Hardness : 80100 HB

Brass Long Inserts

Minimum Order Quantity : 10000 Pieces

Material : Brass

Application : Hardware Fasteners

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS