Triple Hex Brass Inserts

Price 2 INR/ Piece

Triple Hex Brass Inserts Specification

- Standard

- DIN, ISO, BS

- Load Capacity

- Heavy duty

- Tensile Strength

- Up to 350 MPa

- Grade

- CW614N, CW617N

- Corrosion Resistant

- Yes

- Finish

- Polished

- Diameter

- M3 to M10 (custom sizes available)

- Head Type

- Triple Hex

- Thread Type

- Metric, Imperial

- Torque

- High torque resistance

- Capacity

- High load bearing

- Fasteners Type

- Insert

- Material

- Brass

- Tolerance

- 0.02 mm

- Application

- Plastic Moulding, Electrical Fittings, Automotive

Triple Hex Brass Inserts Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 200000 Pieces Per Year

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Boxes

- Main Export Market(s)

- Asia, Australia, Eastern Europe, Western Europe, Middle East, Central America, South America, North America, Africa

- Main Domestic Market

- All India

About Triple Hex Brass Inserts

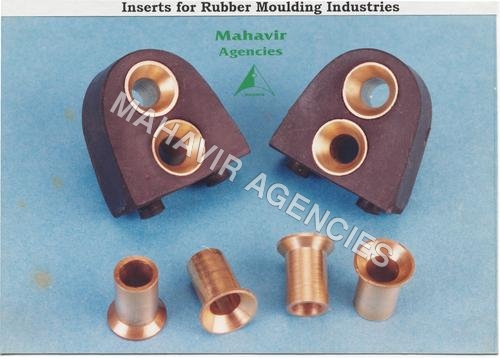

Triple Hex Brass Inserts

We are manufacturer and exporter of Triple Hex Brass Inserts. We have wide range available in brass inserts. We can provide in Round Inserts, Hex Inserts, Square Inserts, Knurling Inserts, Threaded Inserts and as per customer's requirement.

Material

Free Cutting Brass IS 319 Type (l)

Free Cutting Brass as per BS 249 Type(I)

Generally Free Machine Grade of CuZn37Pb3 equivalent to BS 2874 is used to manufacture various brass threaded inserts in form of round, Hexagon, Square etc

Other grades which are followed as per custom requirements are CZ 121, CZ 131, C3604, CDA 360, and DTD 627 etc

High Grade Free Cutting Brass.

Any Special Brass Material Composition as per customers requirement

Threads

ISO Metric (MM Threads)

BA Threads

BSW Threads (Inches)

UNC, UNF,UNEF and NPT Threads

BSP & BSPT (Parallel & Taper Threads)

Any threads as per specifications

Features

Thread as per international Go and Not Go Gauge Standard.

Deep Groove for maximum Pull out Resistance.

Inner Diameter (ID) after threading with very close tolerance to prevent unrequired flush to enter into brass inserts.

Application

Plastic Industry

Rubber Industry

Electronic Industry

Electrical Industry,etc...

High-Performance Fastening Solutions

Our Triple Hex Brass Inserts offer unparalleled strength, reliable holding power, and corrosion resistance, making them perfect for use in high-stress applications. They excel in plastic moulding, electrical installations, and automotive assemblies, supporting heavy-duty load requirements and high torque forces.

Customizable to Your Specifications

Not only are various diameters and thread types available, but our inserts can also be tailored to your specific requirements, following detailed drawings or physical samples. Choose from metric or imperial threads, and request lead-free versions if needed for your industry standards.

Efficient and Secure Installation

Designed for ultrasonic or heat-fit installation, these inserts ensure quick, secure, and precise placement in plastic components. Their triple hex design makes them suited for applications where high torque and heavy load bearing are essential, providing stability and longevity within the assembly.

FAQs of Triple Hex Brass Inserts:

Q: How are Triple Hex Brass Inserts installed into plastic components?

A: Triple Hex Brass Inserts are designed for ultrasonic or heat fit installation methods. Both techniques apply heat or vibration to embed the insert securely into plastic, ensuring strong retention and preventing loosening under torque or heavy loads.Q: What are the benefits of using triple hex head brass inserts?

A: The triple hex head design offers enhanced torque resistance, prevents rotation during and after installation, and delivers superior load-bearing capacity. This makes them ideal for high-stress environments such as automotive, electrical, and plastic moulding applications.Q: Can I request custom sizes or lead-free options for these inserts?

A: Yes, we provide customization based on your drawings or samples, accommodating special sizes or designs as required. Lead-free versions are available upon request to meet specific industry regulations.Q: What is the typical order process for Triple Hex Brass Inserts?

A: To place an order, specify your required diameter (M3M10 or custom), thread type, any special material or finish needs, and minimum quantity (1000 pcs). We offer packaging in polybags, carton boxes, or as per your requirements.Q: Where are these inserts commonly used?

A: Triple Hex Brass Inserts are frequently employed in plastic moulding, electrical fittings, and automotive assemblies due to their high strength, corrosion protection, and versatility in both metric and imperial thread systems.Q: How do these brass inserts comply with quality and environmental standards?

A: Our inserts conform to international standards such as DIN, ISO, and BS. They are RoHS compliant, ensuring a reduction in hazardous substances, and can be supplied as lead-free if required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Moulding Inserts Category

Brass Knurling Inserts

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 10000 Pieces

Material : Other, Brass (IS 319, BS 249, as per requirement)

Tolerance : 0.01 mm

Thread Type : Other, Metric, UNC, UNF, BSP, BA, or custom

Torque : Available as per custom requirements

Brass Helical Knurled Inserts

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 10000 Pieces

Material : Other, High Grade Brass

Tolerance : 0.05 mm

Thread Type : Other, Metric, UNC, UNF, BSW

Torque : High Torque Resistance

Brass Hex Inserts

Minimum Order Quantity : 10000 Pieces

Material : Brass

Tolerance : As per clients requirement Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS