Brass Helical Knurled Inserts

Brass Helical Knurled Inserts Specification

- Shape

- Helical Knurled Round

- Grade

- CW614N / CW617N

- Thickness

- As per customer drawing

- Torque

- High Torque Resistance

- Head Type

- No Head (Straight Insert)

- Feature

- Easy Installation, High Grip Strength, Precise Threads

- Diameter

- 3 mm to 20 mm

- Standard

- DIN, ISO, BS, IS

- Finish

- Polished or Plated

- Capacity

- Custom As Required

- Tensile Strength

- Up to 400 MPa

- Drive Type

- Press Fit or Ultrasonic

- Thread Type

- Metric, UNC, UNF, BSW

- Load Capacity

- Suitable for High Loading Applications

- Corrosion Resistant

- Yes

- Fasteners Type

- Insert

- Material

- High Grade Brass

- Tolerance

- 0.05 mm

- Application

- Plastic Moulding, Thermoplastics, Electrical, Automobile

Brass Helical Knurled Inserts Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 200000 Pieces Per Month

- Delivery Time

- 15 Days

About Brass Helical Knurled Inserts

Brass Helical Knurled Inserts

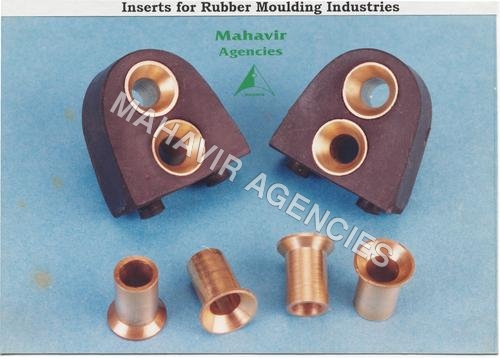

We are manufacturer and exporter of Brass Helical Knurled Inserts. We have wide range available in brass inserts. We can provide in Round Inserts, Hex Inserts, Square Inserts, Knurling Inserts, Threaded Inserts and as per customer's requirement.

Material

Free Cutting Brass IS 319 Type (l)

Free Cutting Brass as per BS 249 Type(I)

Generally Free Machine Grade of CuZn37Pb3 equivalent to BS 2874 is used to manufacture various brass threaded inserts in form of round, Hexagon, Square etc

Other grades which are followed as per custom requirements are CZ 121, CZ 131, C3604, CDA 360, and DTD 627 etc

High Grade Free Cutting Brass.

Any Special Brass Material Composition as per customers requirement

Threads

ISO Metric (MM Threads)

BA Threads

BSW Threads (Inches)

UNC, UNF,UNEF and NPT Threads

BSP & BSPT (Parallel & Taper Threads)

Any threads as per specifications

Features

Thread as per international Go and Not Go Gauge Standard.

Deep Groove for maximum Pull out Resistance.

Inner Diameter (ID) after threading with very close tolerance to prevent unrequired flush to enter into brass inserts.

Application

Plastic Industry

Rubber Industry

Electronic Industry

Electrical Industry,etc...

Superior Holding Power

The helical knurled surface on these brass inserts ensures exceptional grip within plastic and thermoplastic assemblies. This design maximizes torque resistance, preventing rotation or pull-out even under high-load conditions. The combination of high-grade brass material and precision knurling delivers optimal strength and reliability for long-lasting performance.

Wide Customization Options

These inserts can be tailored for diverse projects, with customization available for size, length (3 mm30 mm), diameter (3 mm20 mm), thread type (Metric, UNC, UNF, BSW), and surface finish (polished or plated). Inner thread sizes from M2 to M12, or other specifications, ensure compatibility with most fastening systems. Custom capacities and finishes make them suitable for various industrial requirements.

High Temperature and Corrosion Resistance

Manufactured with premium brass alloys and polished/plated finishes, these inserts are designed to resist corrosion and withstand temperatures up to 300C. They offer stable performance in challenging environments, making them ideal for automotive, electrical, and demanding industrial settings requiring durability and longevity.

FAQs of Brass Helical Knurled Inserts:

Q: How are Brass Helical Knurled Inserts installed into plastic or thermoplastic materials?

A: Brass Helical Knurled Inserts are typically installed using press-fit or ultrasonic insertion methods. The helical knurling allows the insert to grip securely within pre-formed holes, providing high torque resistance and preventing rotation or pull-out under load.Q: What customization options are available for these inserts?

A: These inserts can be customized in terms of length (3 mm to 30 mm), diameter (3 mm to 20 mm), internal thread size (M2 to M12 or as specified), knurl pattern, and surface finish (polished or plated). Thread types such as Metric, UNC, UNF, and BSW are also supported as per customer requirements.Q: Where are these brass inserts commonly used?

A: Brass Helical Knurled Inserts are widely used in plastic moulding, thermoplastics, electrical appliances, automobile assemblies, and other demanding engineering applications that require secure fastening solutions and high mechanical strength.Q: What process ensures the high grip strength and precise threads of these inserts?

A: A precision machining process combined with helical knurling and advanced quality control methods produce high grip strength, accurate thread profiles, and uniform tolerances (0.05 mm), ensuring optimal fit and performance.Q: What are the main benefits of using brass helical knurled inserts?

A: Key benefits include easy installation, high torque and load resistance, corrosion protection, RoHS compliance, and the ability to withstand temperatures up to 300C. The inserts ensure stable, long-term fastening in a variety of industrial environments.Q: When should a customer consider using custom inserts instead of standard options?

A: Custom inserts are ideal when standard sizes or thread types do not meet specific application needs, such as unique material thickness, different mechanical requirements, or special surface finishes. The manufacturer can accommodate custom capacities and designs based on detailed customer drawings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Brass Moulding Inserts Category

Brass Round Inserts

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 10000 Pieces

Material : Brass

Head Type : Round

Torque : Custom, based on application

Grade : CW614N / IS 319 / CZ121 / FreeCutting Brass

Brass Threaded Inserts Nut

Price Range 10.00 - 100.00 INR / Piece

Minimum Order Quantity : 10000 Pieces

Material : Brass

Head Type : Round, Hex, Square (as per design)

Torque : Up to 10 Nm

Grade : CW614N / CZ121

Triple Hex Brass Inserts

Minimum Order Quantity : 5000 Pieces

Material : Brass

Head Type : Triple Hex

Torque : High torque resistance

Grade : CW614N, CW617N

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free